Ensuring Medical Precision: Advanced Balloon Leakage Testing by SmartBalloon Medical Technology

In the highly regulated and precision-driven field of medical device manufacturing, product reliability is paramount—especially for devices such as balloon catheters, dilation balloons, and stent delivery systems. SmartBalloon Medical Technology stands at the forefront of innovation with its robust and highly accurate balloon leakage test systems, which ensure safety, performance, and compliance with international medical standards.

What Is a Balloon Leakage Test?

A balloon leakage test is a critical quality control procedure used in the manufacturing of medical balloons. It evaluates whether a medical balloon maintains air or fluid pressure under stress, ensuring that there are no micro-holes, weak seams, or material defects that could lead to failure during clinical use.

This testing is essential in:

-

Balloon catheters

-

PTA and PTCA balloons

-

Esophageal and ureteral dilation balloons

-

Stent delivery systems

Failure in these devices could lead to serious complications, making leakage testing a vital step in guaranteeing patient safety and product integrity.

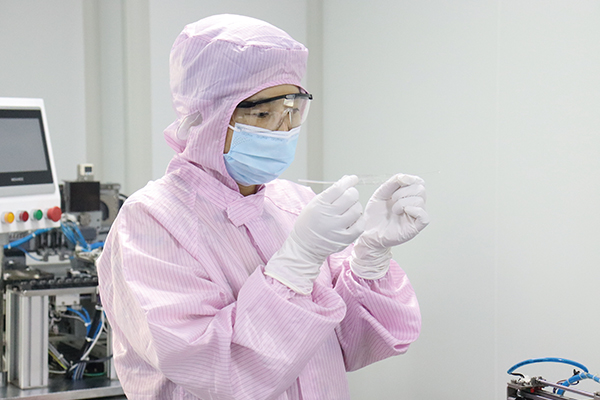

SmartBalloon Medical Technology: Setting the Standard

SmartBalloon Medical Technology is a specialized manufacturer and innovator in the field of medical balloon systems. With decades of expertise and a deep understanding of material science and device engineering, the company has developed high-precision balloon leakage test systems tailored for modern clinical and production requirements.

Features of SmartBalloon’s Balloon Leakage Testing System

-

High Sensitivity Pressure Detection

The system can detect even the smallest pressure drops using ultra-sensitive sensors, allowing for precise identification of micro-leaks that may not be visible under conventional inspection. -

Automated Test Cycles

The entire process—from balloon inflation to pressure monitoring and result logging—is automated for consistency, speed, and repeatability, reducing human error in mass production environments. -

Configurable Parameters

Custom test pressures, inflation volumes, and test durations can be set according to different product specifications and regulatory standards (e.g., ISO 10555, ISO 7198). -

Real-Time Monitoring and Data Logging

Test data is recorded in real-time and can be stored for traceability and regulatory documentation. This feature is especially important for GMP and FDA-compliant facilities. -

Multi-Channel Testing Capability

To support high-volume production, the system can be configured to test multiple balloons simultaneously with independent monitoring channels. -

Leak Localization Option

Advanced models include optional sensors or dye-based systems that can pinpoint the exact location of a leak, streamlining troubleshooting and product refinement.

Applications and Use Cases

SmartBalloon’s leakage testing solutions are widely used in:

-

Medical balloon catheter manufacturing

-

OEM testing for contract medical device developers

-

R&D labs for balloon material development

-

Quality assurance labs in hospitals and regulatory inspection units

The system is adaptable for various balloon sizes and shapes, including tapered, spherical, cylindrical, and multi-lumen designs.

Commitment to Quality and Compliance

At SmartBalloon Medical Technology, quality assurance isn’t just a requirement—it’s a core value. Every balloon leakage test system is designed and validated to meet the rigorous demands of the medical device industry. The company adheres to ISO 13485 standards and supports validation protocols such as IQ/OQ/PQ documentation.

Partner With SmartBalloon

With a global client base and a reputation for engineering excellence, SmartBalloon Medical Technology is the trusted partner for medical device manufacturers seeking reliability, innovation, and precision in their testing processes

https://www.smartballoon.net/Related-Service

www.smartballoon.net

SmartBalloon Medical Technology