How to Choose the Right Slag Pot for Your Smelting or Metal Casting Operation

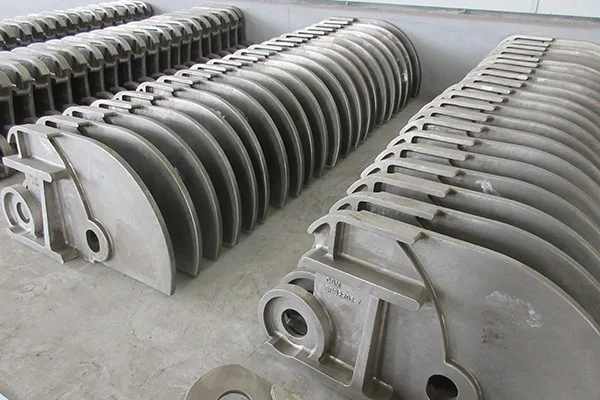

In the heavy industrial sectors of smelting and metal casting, every piece of equipment plays a crucial role in maintaining safety, efficiency, and productivity. Among these, the slag pot—also known as a slag ladle or slag pan—is an indispensable component used for collecting, storing, and transporting molten slag generated during metal production. Choosing the right slag pot is vital to ensure smooth operations, prevent accidents, and prolong equipment lifespan.

China Special Metal Group Limited (CSM) is a professional supplier of cast steel components for metallurgical machinery, cement and mining machinery, building materials machinery, ceramic industries, forging industries, shipbuilding, and chemical industries. CSM is dedicated to providing high-quality cast steel parts, precision machining products, and welded fabrications that meet international standards and support global industrial needs.

This article will guide you through the key factors to consider when choosing the right slag pot for your smelting or casting operation.

1. Understand the Purpose and Process Requirements

Before selecting a slag pot, it’s essential to assess your production process. Different metallurgical operations—such as steelmaking, copper smelting, or aluminum refining—generate different types of slag, each with unique chemical and thermal properties.

For example, steel plant slag tends to have higher temperatures and more corrosive elements compared to non-ferrous smelting slag. Therefore, the slag pot must be made from a material that can withstand extreme heat, thermal shock, and corrosion. CSM offers cast steel slag pots precisely engineered to meet these demanding conditions.

2. Choose the Right Material Composition

The durability of a slag pot largely depends on its steel grade and casting quality. High-quality cast steel provides excellent mechanical strength, high-temperature resistance, and impact toughness.

CSM’s slag pots are manufactured using advanced casting technology and undergo heat treatment and stress relief processes to improve structural integrity and prevent deformation under repeated thermal cycling. The company ensures uniform wall thickness and precise composition control to enhance longevity and operational safety.

3. Capacity and Design Customization

Slag pots come in various capacities—from 1m³ to over 30m³—depending on the scale of your furnace and slag generation rate. A pot that’s too small can cause overflow and safety hazards, while one that’s too large can reduce handling efficiency.

CSM provides customized design and manufacturing based on clients’ furnace type, slag volume, and handling systems. Their engineering team uses 3D modeling and finite element analysis (FEA) to ensure optimal shape, balance, and heat distribution, maximizing operational performance.

4. Structural Strength and Safety Features

Since slag pots handle molten slag at temperatures exceeding 1,500°C, their structural strength is critical. Look for designs that incorporate reinforced ribs, solid trunnions, and balanced geometry to handle heavy loads during lifting and tilting.

CSM’s slag pots are mechanically tested for load-bearing capacity and designed for seamless integration with various handling systems such as overhead cranes, slag cars, and ladles. The company’s precision engineering ensures safe and efficient discharge during slag pouring or dumping operations.

5. Heat Resistance and Thermal Shock Performance

Thermal stress is a major cause of slag pot failure. When molten slag is poured into a cold pot, it can cause cracking, deformation, or spalling. To prevent this, CSM uses heat-resistant alloys and controlled casting techniques to improve the pot’s ability to withstand sudden temperature fluctuations.

Additionally, their slag pots undergo controlled preheating and post-casting treatment, enhancing resistance to thermal fatigue and extending service life under harsh working conditions.

6. Maintenance, Longevity, and Lifecycle Cost

A good slag pot isn’t just about the initial purchase—it’s about long-term performance. Opt for a pot that offers easy maintenance, minimal cracking, and consistent performance across multiple cycles.

CSM’s slag pots are known for their long service life, reducing replacement frequency and operational downtime. The company also provides inspection and repair services, helping clients optimize total cost of ownership (TCO).

7. Partnering with a Reliable Supplier

Selecting a reliable supplier is as important as choosing the right slag pot itself. A reputable manufacturer will ensure quality assurance, on-time delivery, and after-sales support.

With decades of experience, China Special Metal Group Limited (CSM) has become a trusted partner in the global metallurgical industry. Through advanced production techniques, strict quality inspection, and a customer-oriented approach, CSM delivers cast steel slag pots that exceed expectations in durability, precision, and safety.

Conclusion

Choosing the right slag pot for your smelting or metal casting operation requires careful consideration of material quality, design, heat resistance, and supplier reliability. A well-engineered slag pot not only enhances production safety and efficiency but also reduces long-term operational costs.

With its strong technical capabilities and proven industry expertise, China Special Metal Group Limited (CSM) provides tailored slag pot solutions that meet the toughest industrial demands. Whether for steel, copper, or other metal production, partnering with CSM ensures that your operations run smoothly, safely, and efficiently.

www.special-metal.com

China Special Metal Group Limited (CSM)