Innovative Applications of Jwell PVC Extruder in Plastic Processing

Understanding the Jwell PVC Extruder and Its Core Functionality

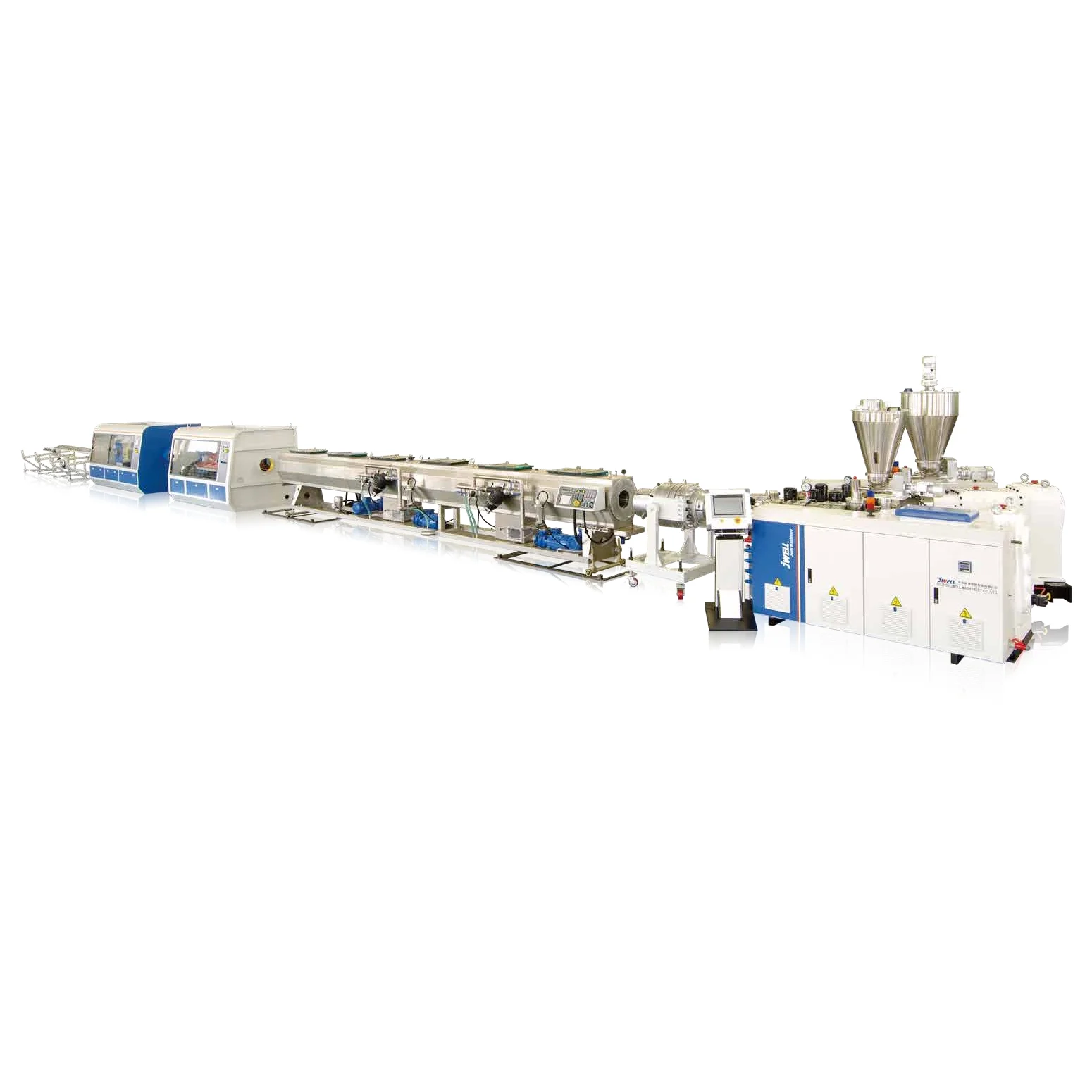

The Jwell PVC extruder represents the forefront of polymer processing technology, engineered to transform polyvinyl chloride (PVC) materials into various high-quality end products. As a critical component in the plastic extrusion industry, this machine converts raw PVC compounds into continuous profiles, sheets, or pipes with consistent density, strength, and surface finish.

At the heart of every Jwell extruder lies a precisely designed screw and barrel system. Through controlled heating, melting, and pressurization, the machine ensures uniform material flow. This process maintains optimal thermal stability and molecular integrity, which are essential for producing durable and dimensionally accurate PVC products. As high performance Jwell plastic machinery exporter, this blog post will share innovative applications of Jwell PVC extruder in plastic processing.

Jwell Twin-Screw PVC Extruder for Pipe and Profile Production

Among Jwell’s wide range of extrusion equipment, the twin-screw PVC extruder stands out for its ability to produce large-diameter pipes, window profiles, and panel boards. The co-rotating twin screws enable superior plasticizing efficiency and homogenization of PVC compounds, crucial for high-performance pipe extrusion lines.

The machine’s modular design allows flexibility in processing both rigid and soft PVC materials. Advanced temperature control zones and torque transmission systems stabilize extrusion pressure, ensuring the finished pipes or profiles meet stringent dimensional and mechanical standards required in modern construction and industrial applications.

Applications of Jwell PVC Extrusion Lines in Diverse Industries

The Jwell PVC extrusion line has found its way into numerous industrial sectors. In construction, it is used for manufacturing pipes, window frames, and decorative panels. In automotive and electrical fields, PVC extrusions provide insulation, weather resistance, and lightweight structural components.

Jwell’s technology supports the extrusion of multilayer and co-extruded PVC products, integrating recycled or specialty materials for environmental compliance and cost efficiency. The machine’s adaptability makes it suitable for producing customized profiles for furniture, packaging, and signage industries as well.

Energy-Efficient Design and Process Optimization in Jwell PVC Extruder

Modern manufacturing emphasizes sustainability, and the energy-efficient Jwell PVC extruder aligns with that direction. Through servo-driven motors, intelligent temperature control systems, and precision screw geometry, Jwell reduces energy consumption without compromising output stability.

Process optimization features, such as real-time torque monitoring and automated feeding systems, minimize material waste and ensure consistent product quality. The integration of smart control panels also allows operators to adjust process parameters quickly, improving operational reliability and reducing downtime during production shifts.

Material Compatibility and Customization in Jwell PVC Extrusion Machines

A key strength of the Jwell PVC extrusion machine lies in its versatility across different PVC formulations. It can handle rigid, flexible, and foamed PVC with equal precision, catering to applications that demand distinct mechanical and aesthetic properties.

Moreover, Jwell supports customization in screw design, extrusion head configuration, and die calibration to match specific production needs. For instance, when producing foamed PVC boards, a specially designed cooling and vacuum calibration system ensures uniform cell structure and smooth surface finish. This adaptability allows manufacturers to optimize product performance and reduce secondary processing requirements.

Technological Innovation Driving the Future of PVC Extrusion

Continuous innovation remains the cornerstone of Jwell’s development philosophy. The company integrates digital control technologies and IoT-based monitoring systems into its PVC extrusion equipment. These advancements enable predictive maintenance, remote diagnostics, and performance analytics — transforming traditional extrusion lines into intelligent production systems.

Such innovations contribute to improved resource efficiency and operational transparency. By connecting multiple extruders through centralized control software, manufacturers can coordinate production schedules, analyze energy usage, and maintain consistent product standards across global operations.

Sustainability and Recycling Trends in Jwell PVC Extrusion

In response to global sustainability goals, Jwell PVC extruders are designed to support eco-friendly materials and recycling initiatives. Many models are capable of processing recycled PVC or incorporating bio-based additives, reducing environmental impact while maintaining mechanical performance.

Additionally, Jwell promotes closed-loop extrusion systems where scrap materials from trimming or defective products are reprocessed on-site. This not only minimizes waste but also enhances the overall efficiency of the production line. As environmental regulations tighten, such sustainable practices become increasingly vital for long-term industrial competitiveness.

Why Manufacturers Choose Jwell PVC Extrusion Solutions

Manufacturers across the globe select Jwell PVC extrusion solutions for their balance of precision, scalability, and reliability. The company’s extensive technical expertise, combined with global service support, ensures that each extrusion line operates at peak efficiency under varying industrial conditions.

Whether producing high-pressure water pipes, decorative foamed panels, or electrical conduits, Jwell’s PVC extruders deliver consistency and longevity. Their modular design, automation integration, and continuous innovation position Jwell as a trusted partner in the evolving landscape of plastic manufacturing.

Conclusion

The Jwell PVC extruder is more than a manufacturing tool — it is a strategic asset driving innovation and sustainability in the plastics industry. By merging advanced mechanical design with intelligent process control, Jwell empowers manufacturers to achieve superior quality, energy efficiency, and material flexibility.

As the global demand for PVC products continues to expand, Jwell’s extrusion technology sets a new standard for performance, reliability, and environmental responsibility — redefining what modern plastic processing can achieve.

www.jwellplas.com

Jwell