The Role of Rectangular Connectors in Robotics and Automation Systems

In today’s rapidly evolving industrial landscape, robotics and automation systems play a pivotal role in enhancing efficiency, precision, and overall productivity. Whether in automotive assembly lines, semiconductor manufacturing, or warehouse automation, these systems rely heavily on robust electrical connections to ensure reliable operation. Among the various types of connectors available, rectangular connectors have emerged as a preferred choice due to their versatility, durability, and ability to handle demanding industrial environments.

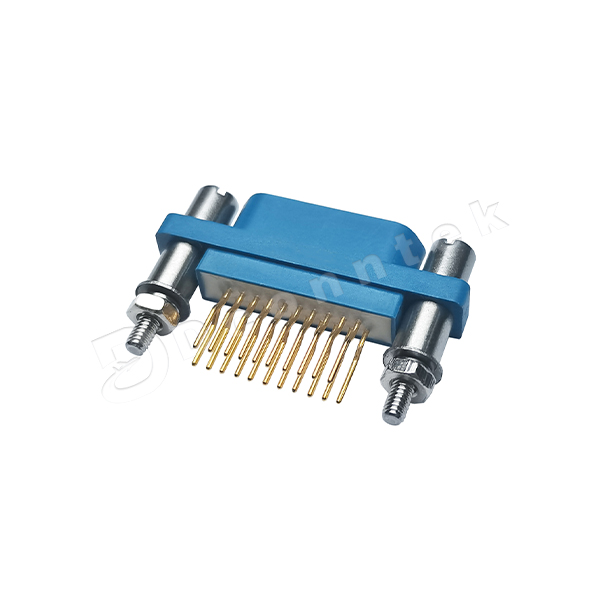

Rectangular connectors are designed with a rectangular housing that allows for multiple contact points in a compact form factor. Unlike circular connectors, which are often used for simpler applications, rectangular connectors can carry higher pin counts and support complex signal, power, and data transmission needs. This makes them particularly suitable for robotics, where multiple sensors, actuators, and control modules need to communicate seamlessly.

Key Benefits of Rectangular Connectors in Robotics

High Density and Flexibility

Robotics systems often integrate numerous components within a confined space. Rectangular connectors are designed to maximize contact density without significantly increasing the footprint. This high-density design allows engineers to connect multiple signal types—including power, data, and control signals—through a single connector. This not only simplifies wiring but also reduces the risk of connection errors and improves system reliability.

Robustness in Harsh Environments

Robots frequently operate in environments with vibration, temperature fluctuations, dust, or moisture. Rectangular connectors are engineered to withstand these challenges. High-quality connectors often feature durable housings, secure locking mechanisms, and materials resistant to corrosion and wear. Companies like Dconntek

specialize in designing custom rectangular connectors and cable assemblies for harsh environments. By collaborating with clients, Dconntek ensures that every solution meets the specific environmental and operational requirements of the application.

Ease of Installation and Maintenance

Maintenance downtime can be costly in automated production lines. Rectangular connectors simplify installation and maintenance by providing clear polarization, keying, and locking features. This ensures that connections are made correctly the first time and reduces the likelihood of damage during repeated maintenance cycles. Modular designs further allow technicians to replace or upgrade individual connectors without extensive rewiring.

Scalability and Customization

As robotics applications evolve, system upgrades often require changes in signal capacity or connector configuration. Rectangular connectors are inherently scalable, supporting multiple contact arrangements, varying current ratings, and hybrid configurations that combine power, signal, and data contacts. Dconntek works closely with clients to deliver personalized connector designs that match these evolving requirements, ensuring long-term compatibility and flexibility.

Enhanced Signal Integrity

Modern robotics systems often transmit high-speed data signals between sensors, controllers, and actuators. Rectangular connectors are engineered to maintain signal integrity even in electrically noisy environments. Shielded variants prevent electromagnetic interference (EMI) and crosstalk, ensuring reliable communication and minimizing errors in mission-critical applications.

Applications of Rectangular Connectors in Robotics

Industrial Automation: Robotic arms on assembly lines require connectors that can handle multiple sensor inputs and power lines. Rectangular connectors provide the necessary density and durability to maintain uninterrupted operations.

Autonomous Vehicles: Self-driving forklifts and AGVs rely on robust connectors to transmit control signals and sensor data accurately, even in environments with vibration and temperature extremes.

Medical Robotics: Precision surgical robots use connectors that guarantee stable connections for high-speed data transmission and sensitive feedback signals.

Aerospace and Defense Robotics: Unmanned systems in harsh conditions demand connectors that resist corrosion, shock, and temperature variations while maintaining optimal performance.

Why Partner with a Connector Expert Like Dconntek

Choosing the right connector solution can significantly influence the overall reliability and efficiency of a robotic system. Dconntek has built a reputation as a leading provider of custom-engineered connectors and cable assemblies. By working closely with clients, Dconntek ensures that each solution is tailored to the specific operational, environmental, and electrical requirements of the application.

Some of the advantages of partnering with Dconntek include:

Customization: Design solutions that meet unique application needs, from contact arrangement to cable length and shielding.

Quality Assurance: Consistent manufacturing processes and rigorous testing ensure high reliability and long-term performance.

Rapid Delivery: Streamlined design and assembly processes reduce lead times without compromising quality.

Technical Support: Dedicated engineering teams assist in selecting, designing, and implementing the optimal connector solution.

Future Trends in Robotics Connector Technology

As robotics continues to advance, connector technology will play a critical role in supporting emerging requirements. Some trends to watch include:

Miniaturization: Compact robotic systems require smaller connectors without sacrificing current capacity or signal integrity.

High-Speed Data Transmission: Increasing reliance on real-time analytics and AI-driven control systems demands connectors capable of supporting higher bandwidths.

Hybrid Connectors: Combining power, data, and signal contacts in a single housing reduces complexity and improves system reliability.

Environmental Resilience: Extreme temperature, moisture, and chemical resistance will become standard requirements for connectors in industrial and outdoor robotic applications.

By keeping pace with these trends, companies like Dconntek ensure that their rectangular connectors remain a reliable foundation for next-generation robotics and automation systems.

Conclusion

Rectangular connectors are indispensable components in modern robotics and automation systems. Their high contact density, robustness, ease of installation, and adaptability make them ideal for a wide range of industrial applications. By partnering with a specialized provider like Dconntek, engineers can access tailored solutions that meet the unique demands of their projects, ensuring high performance, reliability, and longevity.

Whether designing an industrial assembly robot, an autonomous vehicle, or a medical robotic system, investing in the right connector technology lays the groundwork for success. In a field where precision and reliability are paramount, rectangular connectors serve as a small but critical element in enabling smarter, faster, and more resilient automation solutions.

www.dconntek.com

Dconntek