What Is a Conveyor Weight Checker? Key Functions and Industrial Uses Explained

In modern manufacturing and packaging environments, maintaining consistent product quality and meeting regulatory weight standards are non-negotiable. That’s where a conveyor weight checker—also known as an in-line checkweigher—plays a crucial role. This intelligent device ensures that every item on a conveyor belt meets pre-set weight criteria, making it a key component of automated production lines.

In this article, we’ll explore what a conveyor weight checker is, how it works, its primary functions, and where it’s most commonly used—while also introducing how industry leaders like Dostar Packing Equipment Co., Ltd are driving automation in this space.

What Is a Conveyor Weight Checker?

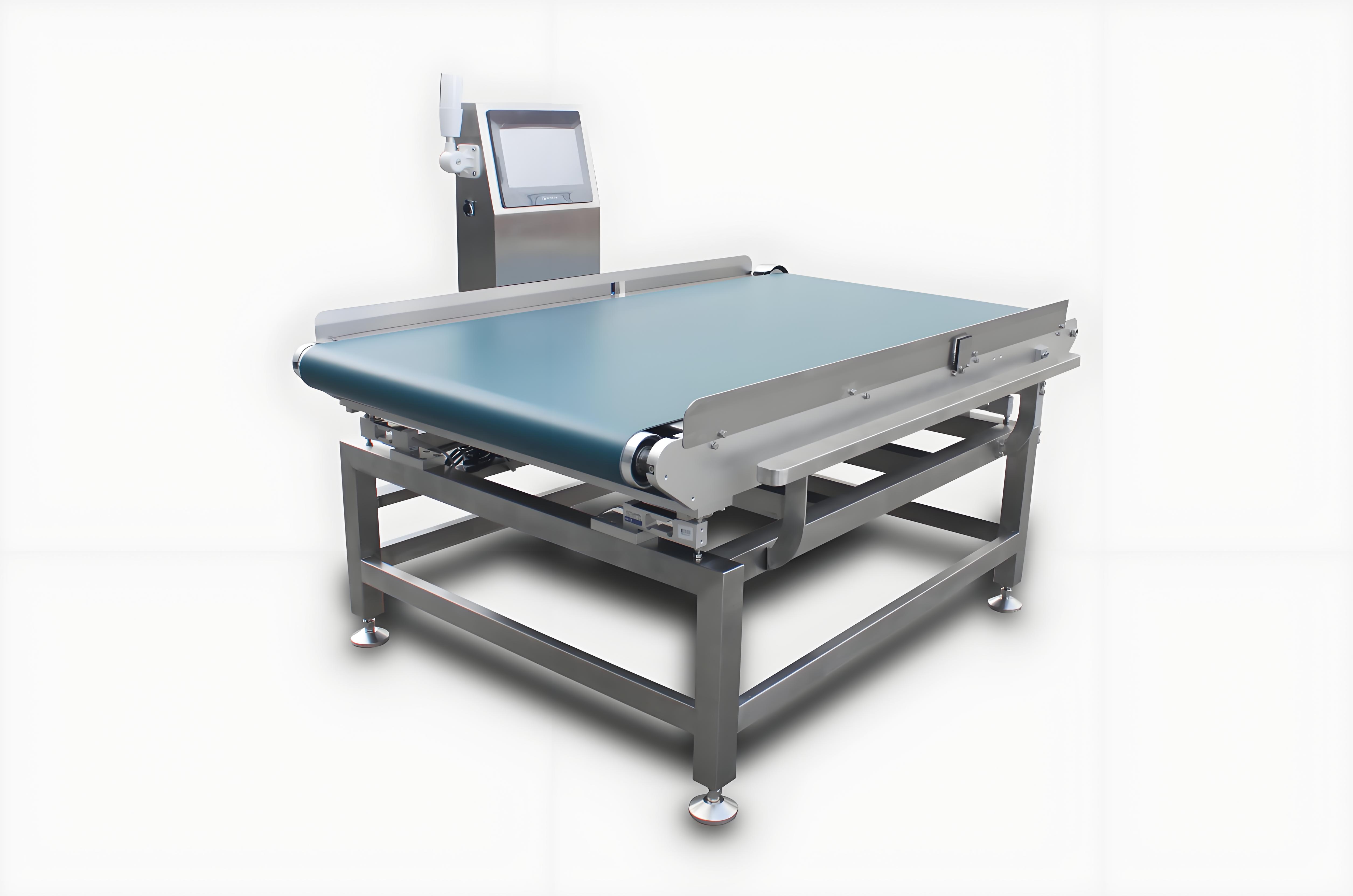

A conveyor weight checker is an automated device used to weigh products as they move along a production line. It performs real-time weight measurement without stopping the conveyor, allowing for non-disruptive, high-speed quality control. These systems are typically equipped with precision load cells and high-speed data processors to measure and sort products based on weight.

It’s a vital tool in ensuring that packaged goods meet specified weight requirements, thereby reducing product giveaway, avoiding underfilled items, and ensuring regulatory compliance.

How Does a Conveyor Weight Checker Work?

Here’s a step-by-step breakdown of the process:

-

Product Enters the System

Items are transferred from the production line onto the weighing platform via a conveyor belt. -

In-Motion Weighing

The load cell measures the product’s weight dynamically—without pausing or slowing down the conveyor. -

Data Processing

The system compares the measured weight with pre-set thresholds stored in its control unit. -

Sorting or Rejection

If the product is outside the acceptable range (overweight or underweight), it is automatically rejected or diverted for rework.

Key Functions of a Conveyor Weight Checker

1. Accurate Weight Control

Ensures every product meets specified weight criteria, reducing compliance risks and material loss.

2. Real-Time Feedback

Provides live data that helps manufacturers adjust filling or dosing systems on the fly.

3. Automated Sorting and Rejection

Detects and removes defective products automatically, improving overall efficiency.

4. Statistical Reporting

Generates detailed logs and reports for quality assurance and traceability.

5. Integration with Production Lines

Can be easily integrated into semi-automated or fully automated packaging systems for seamless operation.

Industrial Applications

Conveyor weight checkers are widely used in industries where weight accuracy is critical:

-

Food & Beverage – Ensuring correct portion sizes in packaged foods, bottled drinks, and snack bags.

-

Pharmaceuticals – Verifying capsule and tablet bottle weights for dosage accuracy.

-

Cosmetics & Personal Care – Monitoring product fill levels in bottles, jars, and tubes.

-

Chemicals & Fertilizers – Controlling weight for powder, granule, or liquid packaging.

-

Logistics & E-commerce – Checking parcel weights for shipping and billing accuracy.

Dostar Packing Equipment Co., Ltd: Precision Automation for Modern Manufacturing

A leader in intelligent packaging solutions, Dostar Packing Equipment Co., Ltd specializes in the R&D, integration, manufacturing, and sales of automated packaging production lines. As a high-tech enterprise, Dostar is dedicated to delivering both semi-automatic systems and fully automated packaging solutions tailored to diverse industry needs.

With a focus on smart integration, Dostar’s conveyor weight checker systems offer:

-

High-precision load cells

-

User-friendly touch interfaces

-

High-speed rejection mechanisms

-

Seamless integration with upstream and downstream packaging equipment

-

Customizable solutions for different product sizes, shapes, and production volumes

Dostar’s commitment to automation, reliability, and customer support has made it a trusted partner for companies seeking to optimize quality control and reduce manual labor on their production lines.

Final Thoughts

A conveyor weight checker is more than just a scale—it's a smart quality control tool that ensures consistency, reduces waste, and improves efficiency across industries. For businesses aiming to streamline operations and stay competitive, investing in a high-quality weight checking solution is a strategic move.

With advanced solutions from companies like Dostar Packing Equipment Co., Ltd, manufacturers can confidently upgrade their packaging lines and meet the demands of modern production.

www.dostar-pack.com

Dostar Packing Equipment (Wuxi) Co., Ltd