Why Choose a Bottom Vacuum Emulsifier Mixer? Benefits for Industrial Formulations

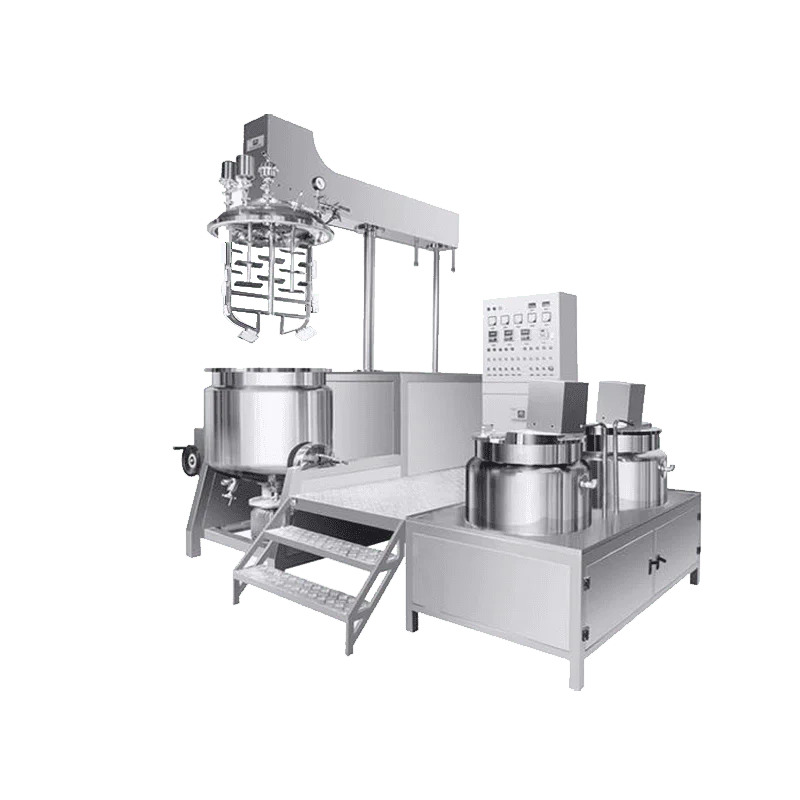

In today’s competitive industrial landscape, the demand for efficient, hygienic, and high-performance mixing technology is more important than ever—especially in sectors like cosmetics, pharmaceuticals, food processing, and chemicals. One standout innovation in this domain is the Bottom Vacuum Emulsifier Mixer, also known as the under emulsifying mixer.

This specialized system offers a range of operational and formulation advantages that make it a superior choice for high-precision emulsification and homogenization. In this article, we’ll explore why bottom vacuum emulsifier mixers are increasingly favored in industrial formulations and how companies like Orisun, a leading machinery design and manufacturing enterprise, are advancing the technology to meet evolving production demands.

What Is a Bottom Vacuum Emulsifier Mixer?

A bottom vacuum emulsifier mixer is a mixing system where the homogenizing rotor is mounted at the bottom of the tank instead of the top. This design allows the motor to transfer power more directly and efficiently to the homogenizer, enhancing mixing performance, especially for viscous materials or small-batch production.

The mixing structure and method are similar to top-mounted mixers (like the ZJR series), but the bottom configuration offers improved shear force, optimized flow patterns, and enhanced material discharge capabilities.

Key Features of Bottom Emulsifying Mixers

Bottom-Mounted Homogenizer: Enables direct and powerful energy transfer, maximizing emulsifying and shearing effects.

Hydraulic Lifting System: Allows for easy access and thorough cleaning of the tank, reducing downtime and contamination risks.

Multi-Functional Stirring Paddles: Designed for compatibility with a wide range of formulation viscosities and process conditions.

PTFE Wall Scraper: Continuously scrapes the tank wall to prevent material buildup and ensure uniform heating and mixing.

316L Stainless Steel Contact Surfaces: Ensures high corrosion resistance, hygiene, and compatibility with sanitary production standards.

300 Mesh Mirror Polish Finish: Applied to tanks and pipelines to meet GMP and daily chemical production hygiene standards.

Benefits for Industrial Formulations

1. Superior Emulsification Performance

Thanks to its bottom homogenizer configuration, this mixer delivers intense cutting, centrifugal action, and shear at the base, ensuring that creams, pastes, and emulsions achieve fine and smooth textures with enhanced stability.

2. Efficient Processing of Small and Viscous Batches

In smaller production runs or when working with high-viscosity formulas, bottom vacuum emulsifiers maximize motor efficiency and ensure consistent emulsification, where top-mounted systems might underperform.

3. Optimized Cleaning and Hygiene

The hydraulic lifting mechanism enables full access to the tank for cleaning, while the mirror-polished interior and PTFE scraper minimize material residue. This design supports CIP (Clean-in-Place) systems and meets the stringent hygiene standards required in cosmetic and pharmaceutical manufacturing.

4. Reduced Production Time and Material Waste

Rapid mixing and more effective homogenization mean faster batch processing. Plus, because the bottom outlet aligns with gravity and the flow pattern, material discharge is more complete, reducing waste.

5. Versatility in Application

This type of mixer is well-suited for:

Creams and lotions

Pharmaceutical ointments

Food emulsions (e.g., mayonnaise, sauces)

Chemical slurries and pastes

Adhesives and coatings

Why Choose Orisun?

When investing in advanced mixing technology, choosing the right manufacturer makes all the difference. Orisun, a company specializing in mechanical design and manufacturing, offers cutting-edge emulsifying systems tailored for precision, durability, and performance.

What Sets Orisun Apart:

Expertise in Custom Engineering: Orisun designs mixers to meet your exact specifications, including tank volume, control systems, and ingredient sensitivities.

Premium Materials and Craftsmanship: All contact parts are made from USU 316 stainless steel, with mirror-polished finishes to ensure compliance with GMP and sanitary standards.

Reliable Automation and Control: Orisun’s vacuum emulsifiers support PLC control, automated temperature regulation, and vacuum defoaming, ensuring consistent results.

Global Support and Innovation: With an eye on international standards and a strong R&D backbone, Orisun serves clients across the globe with forward-thinking machinery solutions.

Conclusion

The Bottom Vacuum Emulsifier Mixer is an advanced solution for industries that demand high-efficiency emulsification with uncompromised hygiene and process control. Whether you’re formulating skincare products, pharmaceutical gels, or chemical pastes, this technology ensures uniform results, faster processing, and greater operational flexibility.

By partnering with a trusted manufacturer like Orisun, you gain access to engineering expertise and reliable equipment that supports long-term production success.

Frequently Asked Questions (FAQs)

Q1: What industries are bottom emulsifier mixers suitable for?

A1: They are ideal for cosmetics, pharmaceuticals, food, and chemical industries—particularly for creams, emulsions, gels, and pastes.

Q2: How does bottom homogenization improve emulsification?

A2: It provides more direct and powerful shear forces, enhancing mixing efficiency and producing finer, more stable emulsions.

Q3: Are Orisun mixers customizable?

A3: Yes, Orisun offers fully customized systems based on tank size, control needs, mixing materials, and industry requirements.

Q4: Is vacuum functionality important in emulsifying mixers?

A4: Yes, vacuum systems remove air bubbles during mixing, resulting in smoother textures and preventing oxidation or contamination.

Common Failures in External Circulation Emulsifying Mixers—And How to Fix Them

www.orisunmachinery.com

Orisun