Unveiling the Unbreakable: Exploring the Frontiers of 3D Printing with Ultra-Strong Materials

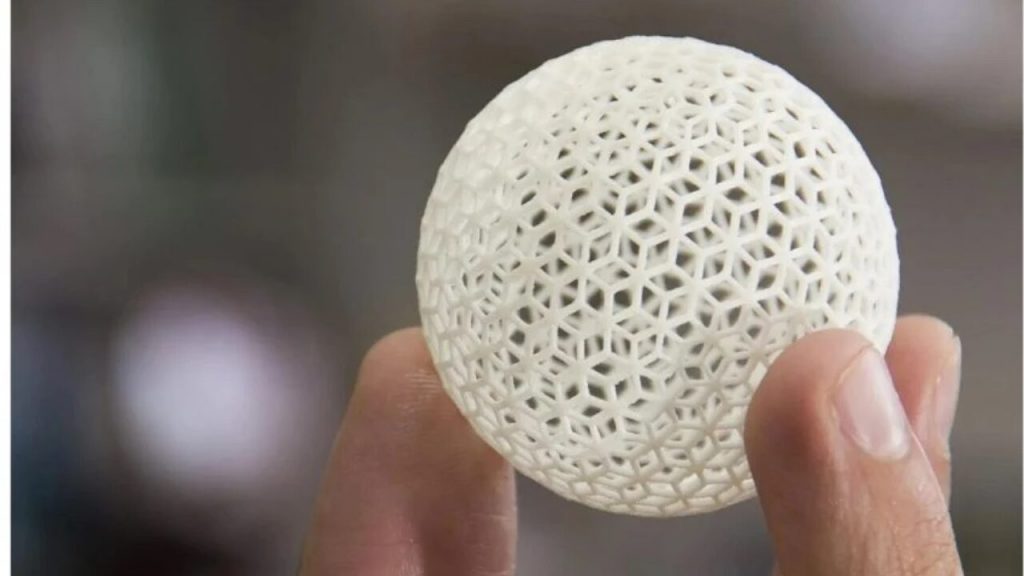

In the realm of 3D printing, the quest for stronger and more durable materials has been a driving force behind technological advancements. Engineers and researchers have been pushing the boundaries of what can be achieved, aiming to create objects that are not only visually appealing but also possess exceptional strength. In this article, we delve into the world of 3D printing and explore the strongest materials that can be used to create astonishingly robust and resilient objects.

- Reinventing Strength: The Evolution of 3D Printing Materials

The journey towards finding the strongest material for 3D printing has been marked by continuous innovation and experimentation. Initially, traditional thermoplastics like ABS and PLA dominated the scene, offering decent strength but limited in their capabilities. However, the emergence of advanced composite materials and metal alloys has revolutionized the field, opening up new possibilities for creating objects with unparalleled strength. - Carbon Fiber Composites: A Leap Towards Superior Strength

Carbon fiber composites have emerged as one of the most promising materials in the realm of 3D printing. By combining the lightweight and high-strength properties of carbon fiber with the versatility of additive manufacturing, engineers have been able to create components that exhibit exceptional strength-to-weight ratios. These composites find applications in aerospace, automotive, and sporting industries, where strength and weight reduction are critical factors. - Titanium: The Metal Marvel

When it comes to metal 3D printing, titanium stands out as a true game-changer. With its remarkable strength, corrosion resistance, and biocompatibility, titanium has found widespread use in industries such as aerospace, medical, and automotive. The ability to 3D print complex geometries with titanium alloys has unlocked new design possibilities, enabling the creation of lightweight yet incredibly strong components. - High-Performance Polymers: Pushing the Limits

Beyond traditional thermoplastics, high-performance polymers have emerged as a class of materials that offer exceptional strength and durability. Polymers like PEEK (Polyether Ether Ketone) and ULTEM (Polyetherimide) possess excellent mechanical properties, chemical resistance, and thermal stability. These materials find applications in industries such as healthcare, aerospace, and electronics, where demanding operating conditions require robust and reliable components. - Continuous Fiber Reinforcement: Taking Strength to the Next Level

In recent years, advancements in 3D printing technology have enabled the integration of continuous fiber reinforcement into printed objects. By combining materials like carbon fiber or fiberglass with thermoplastics, engineers can create parts that exhibit exceptional strength and stiffness. This technique, known as continuous fiber reinforcement, has the potential to revolutionize industries such as automotive, defense, and robotics, where structural integrity is of utmost importance.

Conclusion:

The world of 3D printing continues to push the boundaries of what is possible, and the quest for the strongest materials is an ongoing endeavor. From carbon fiber composites to titanium alloys and high-performance polymers, each material brings its unique set of properties and advantages. As technology advances and new materials are developed, we can expect even more remarkable breakthroughs in the field of 3D printing, paving the way for stronger, lighter, and more resilient objects that will shape the industries of the future.