The Inner Workings of Mechanical Seals: Understanding How They Keep Your Machinery Running Smoothly

Mechanical seals are essential components in many types of machinery, including pumps, compressors, and mixers. They are used to prevent leaks and maintain the integrity of the system, ensuring that it operates efficiently and safely. In this article, we will explore the inner workings of mechanical seals and how they work to keep your machinery running smoothly.

What is a Mechanical Seal?

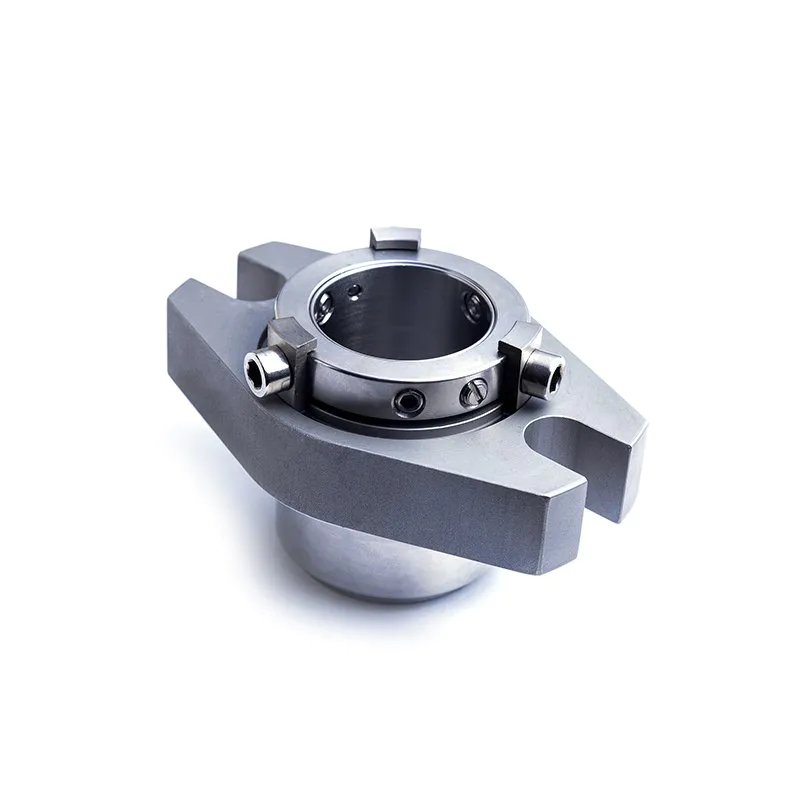

A mechanical seal is a device that is used to seal the gap between two surfaces in a machine. It consists of two main components: a stationary part and a rotating part. The stationary part is usually attached to the machine casing, while the rotating part is attached to the shaft of the machine. The two parts are held together by a spring, which applies pressure to the seal faces.

How Does a Mechanical Seal Work?

When the machine is in operation, the rotating part of the mechanical seal rotates with the shaft, while the stationary part remains fixed. The two seal faces are in contact with each other, creating a seal that prevents fluid from leaking out of the machine.

The seal faces are usually made of materials such as carbon, ceramic, or tungsten carbide, which are chosen for their durability and resistance to wear. The seal faces are also lubricated by a thin film of fluid, which helps to reduce friction and heat.

The spring that holds the two seal faces together applies a constant pressure to the faces, ensuring that they remain in contact with each other. This pressure is critical to the performance of the mechanical seal, as it helps to maintain the seal and prevent leaks.

Types of Mechanical Seals

There are several types of mechanical seals, each designed for specific applications. Some of the most common types include:

- Single Mechanical Seal: This type of seal consists of only one set of seal faces and is used in applications where leakage is not critical.

- Double Mechanical Seal: This type of seal consists of two sets of seal faces and is used in applications where leakage is not acceptable.

- Cartridge Mechanical Seal: This type of seal is pre-assembled and can be easily replaced without disassembling the machine.

- Split Mechanical Seal: This type of seal is designed to be installed without removing the shaft from the machine.

Conclusion

Mechanical seals are critical components in many types of machinery, and understanding how they work is essential to maintaining the integrity of the system. By choosing the right type of mechanical seal for your application and ensuring that it is installed and maintained correctly, you can help to prevent leaks and keep your machinery running smoothly.