The Purpose and Benefits of Dry Seals in Industrial Applications

Dry seals are an essential component in many industrial applications, including pumps, compressors, and turbines. They are designed to prevent the leakage of fluids and gases, which can cause damage to equipment and pose safety hazards. In this article, we will explore the purpose and benefits of dry seals in industrial applications.

What is a Dry Seal?

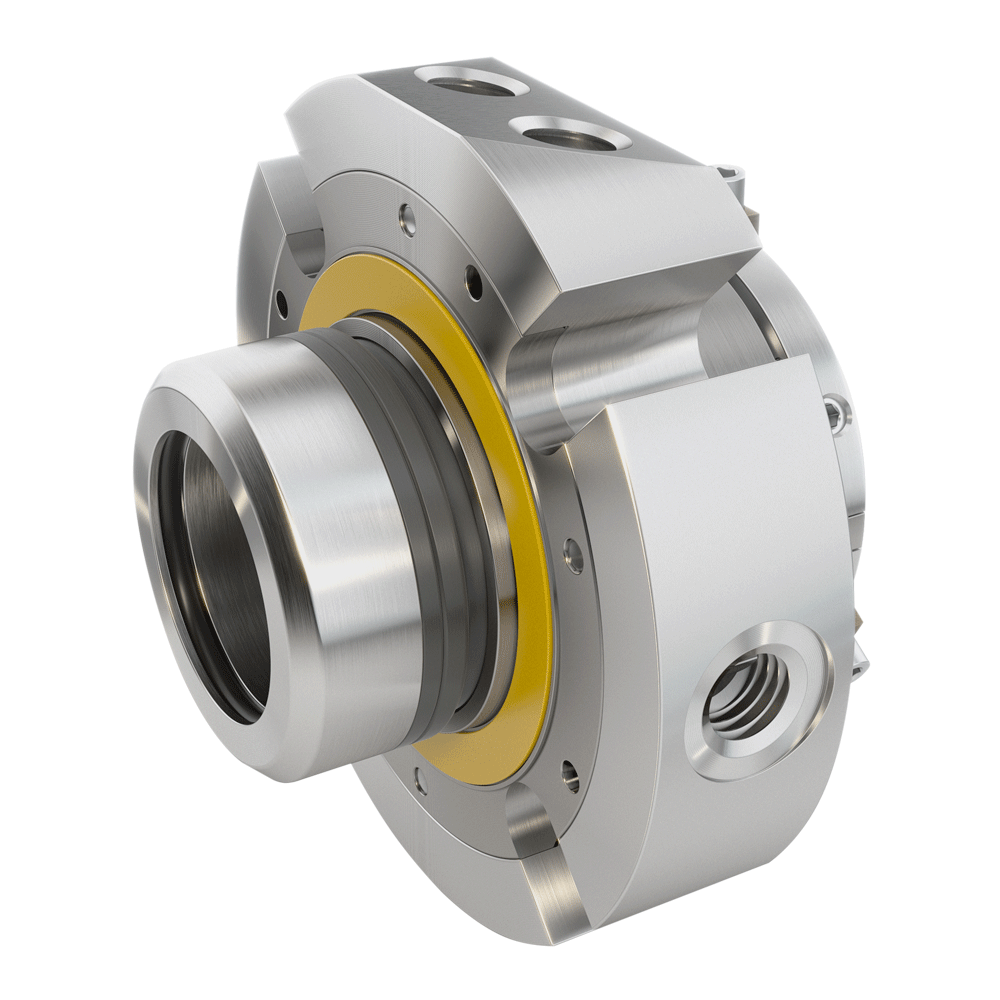

A dry seal is a mechanical seal that uses a stationary and rotating face to create a barrier between two surfaces. The stationary face is typically made of a hard material, such as ceramic or tungsten carbide, while the rotating face is made of a softer material, such as carbon. The two faces are held together by a spring, which applies pressure to maintain contact between the faces.

Purpose of Dry Seals

The primary purpose of a dry seal is to prevent the leakage of fluids and gases in industrial applications. This is important because leakage can cause damage to equipment, reduce efficiency, and pose safety hazards. Dry seals are commonly used in pumps, compressors, and turbines, where they prevent the leakage of fluids and gases from the shaft.

Benefits of Dry Seals

Dry seals offer several benefits over traditional packing seals, including:

- Reduced Leakage: Dry seals are designed to prevent leakage, which reduces the risk of damage to equipment and improves safety.

- Increased Efficiency: Dry seals reduce friction between the rotating and stationary faces, which improves efficiency and reduces energy consumption.

- Longer Lifespan: Dry seals have a longer lifespan than traditional packing seals, which reduces maintenance costs and downtime.

- Reduced Environmental Impact: Dry seals are more environmentally friendly than traditional packing seals, as they do not require lubrication and produce less waste.

Conclusion

Dry seals are an essential component in many industrial applications, where they prevent the leakage of fluids and gases and improve efficiency. They offer several benefits over traditional packing seals, including reduced leakage, increased efficiency, longer lifespan, and reduced environmental impact. By understanding the purpose and benefits of dry seals, industrial operators can make informed decisions about their use in their equipment.